· QQP416 is a federal specification, and is still active even though SAE jumped the gun and issued AMSQQP416 affil link to spec at Techstreet You can get a copy by going to assistdapsmil ednote 03 this address is outdated, see below response for updated address, clicking on the quicksearch button, and typing in the numberAMSQQP416, Type I, Class 3 ASTMB , SC2, Type I, Class 5 over AMSC, Class 4, Grade B e Cadmium Plate, Gold Irridite, Over Electroless Nickel MILC5541, Class 3 AMSQQP416, Type II, Class 3 over AMSC, Class 4, Grade B c Cadmium Plate, Olive drab AMSQQP416, Type II, Class 3, 48 Hours A Cadmium Plate, Olive drab Over Electroless Nickel 1000Nickel Plating We process sulfamate nickel plating class 1 and class 2 with dull or satin finishes that are applied for corrosion protection The nickel plating process can be applied as an underplate for chrome for the

Ccr274ss A Cres Solid Film Lube Passivate Ccr274cs P E R Per Per Per Ms604r Ams 5731 Astm A 493 Mil L Qq P 35 L F Pdf Free Download

Ams-qq-p-416 type 2

Ams-qq-p-416 type 2-Cadmium Plate C2 AMSQQP416 Type II Class 2 Chem Film MILDTL5541, Type I, Class 1A (Gold) Chrome AMS 2460 Gold MILDTL454, Type II, Class 0 Nickel Plate N AMSQQN290, Class 1, Grade G Passivate P AMS 2700 Method 1, Type2, Class 1 (copper sulfate test) Phosphate PH MILDTL, Type Z, Class 2 Silver Plate S ASTM 00 Tin Plate T1 ASTM B545, ClassFED QQP416F Cadmium Plating ENS Technology provides complete cadmium plating for military, defense, and other noncommercial applications We deliver cadmium platings to meet FED QQP416F, ASMQQP416E, and other applicable specifications Contact ENS today for

An3 5a 100 Bolts Akcustom Hex Bolts

II) on electrodepositedcadmium QQP416F The prime purpose of chromate finishes (Type platings is to retard or prevent the formation of white corrosion products on surfaces exposed to stagnant water, high humidity atmospheres, salt water, marine atmospheres, orOperating Temperature Range65 – 175;AMSQQP416, Type I, Class 3 ASTMB , SC2, Type I, Class 5 over AMSC, Class 4, grade B e Cadmium Plate, gold Irridite, over Electroless Nickel MILC5541, Class 3 AMSQQP416, Type II, Class 3 over AMSC, Class 4, grade B c Cadmium Plate, olive drab AMSQQP416, Type II, Class 3, 48 Hours A Cadmium Plate, olive drab over Electroless Nickel 1000 Hour

AMSQQP416, TypeI, Class2 U Cadmium, Olive Drab AMSQQP416, TypeII, Class3 V Cadmium, Olive drab over Electroless Nickel AMSQQP416, TypeII, Class3 (Cadium);AMSC, Class4, GradeB (Nickel) W W Cadmium, Olive drab over Electroless Nickel To meet AS requirements Y ZincCobalt, Dark Olive drab ASTMBB40 Z ZincCobalt, BlackF5000 (*) Cadmium plate per AMSQQP416, Type II, Class 2 plus Kaylube molybdenum disulfide dry film lubricant per AS5272, Type I F5000X (*) Cadmium plate per AMSQQP416, Type II, Class 2 F5000 (*)CW Cadmium plate per AMSQQP416, Type II, Class 2 and carbowax PERFORMANCE NASM

AMSQQP416, Type II, Class 3 over Electroless Nickel, AMSC, Class 3 or 4, Grade B AMSQQP416, Type II, Class 3 ASTMB , Over Electroless Nickel 1000 Hour Salt Spray COMPONENT Machined components such as backshell bodies, fabricated elbows, protective covers, rotatable couplers, dummy stowage receptacles, lock nuts, Gspring support rings, EMIQQP416F, FEDERAL SPECIFICATION PLATING, CADMIUM (ELECTRODEPOSITED) (01 OCT 1991) S/S BY SAEAMSQQP416, This specification covers the requirements for electrodeposited cadmium platingAMSQQP416, TypeI, Class2 U Cadmium, Olive Drab AMSQQP416, TypeII, Class3 V Cadmium, Olive drab over Electroless Nickel AMSQQP416, TypeII, Class3 (Cadium);

Qq P 416 Tech Information

Cadmium Plating Macon Georgia

I just wanted to send a quick "Thank you" to you and your team for helping us get through a tough few weeks of "Hot/Critical" parts!Adapter Plating Material Cadmium (AMSQQP416, Type II, Class 3) TE Adapter Code 40;Finish Cadmium plated per AMSQQP416, Type II, Class 1 and baked Heat treated components per AMSH6875 Weight 096 oz / 272 gm Threaded Stud Threaded Stud Thread Size 3/ 4 UNF 3A Finish Cadmium plated per AMSQQP416 Load Capacity 4,000 lbs in any direction Weight 144 oz / 408 gm ·16 oz / 454 gm Threaded Studs — These multi

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

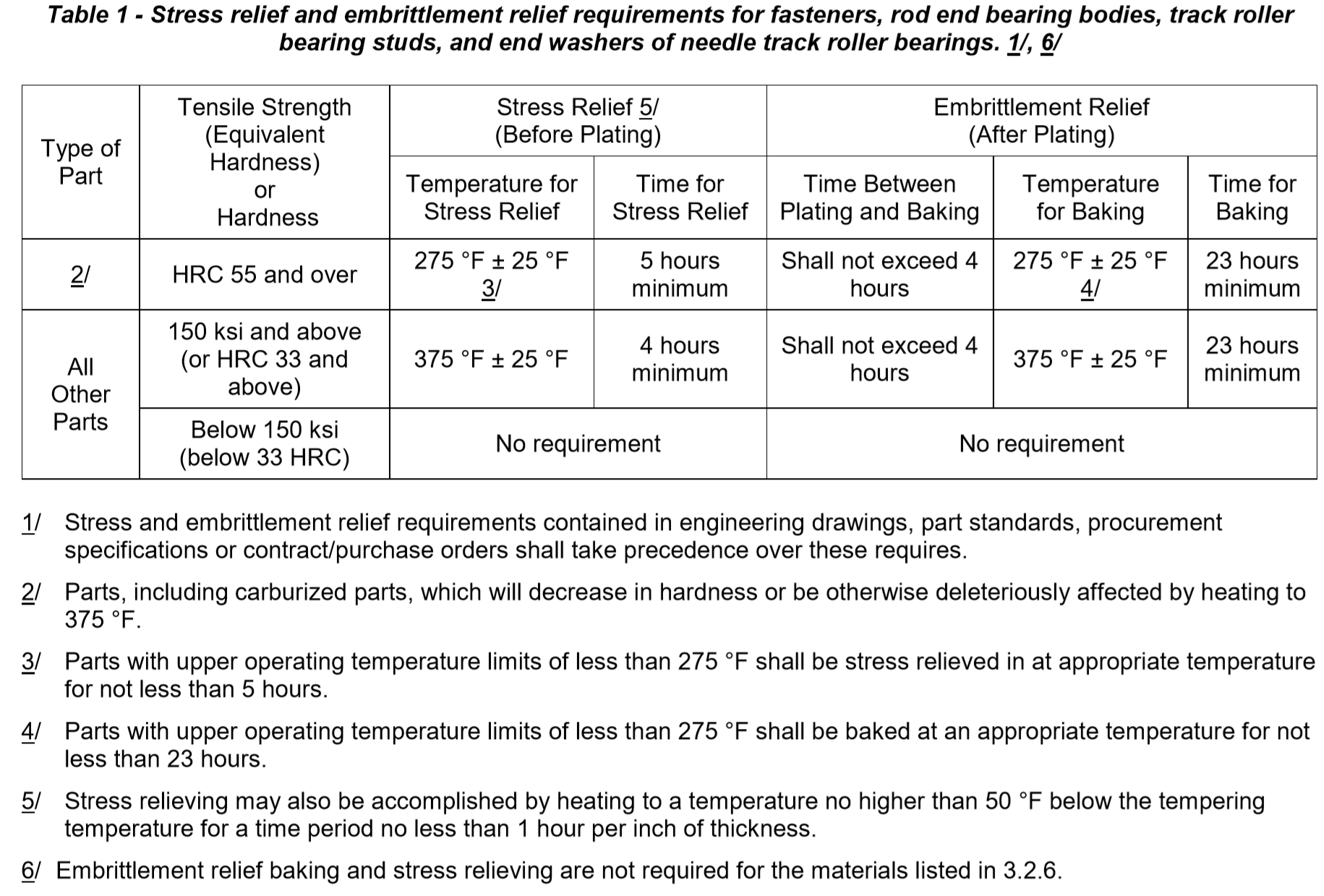

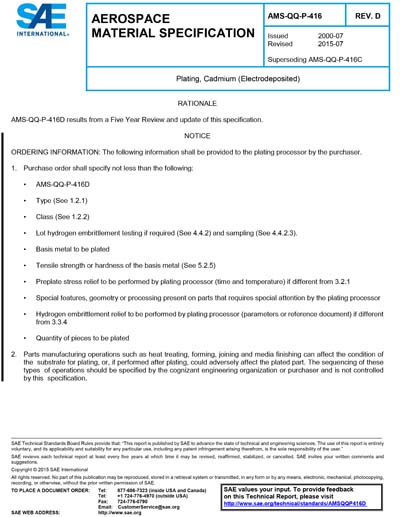

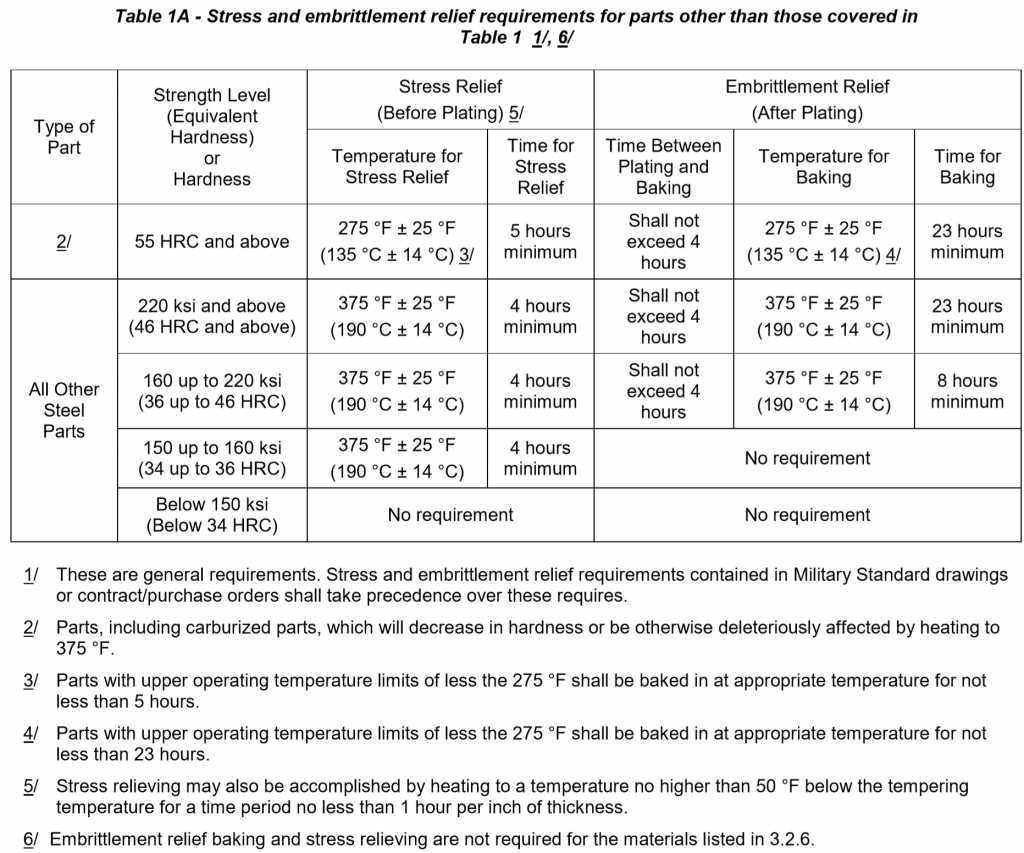

Revision E of AMSQQP416 corrects the errors in Table 1a and removes the "24 hours minimum" from the drying time requirement of 3281 NOTICE ORDERING INFORMATION The following information shall be provided to the plating processor by the purchaser 1 Purchase order shall specify not less than the following • AMSQQP416E • Type (see 111) • Class (see 112) • LotAMSQQP416 Class I " minimum thickness Class II " minimum thickness Class III " minimum thickness Type I As plated Type II With chromate treatment Type III With phosphate treatment Colorless Irridescent Bronze Brown Olive Drab Yellow Forrest Green Primarily used to protect steel and cast iron against corrosion Chrome Plating QQC3 AMSPost Plate Treatment Cadmium Plate, per SAE AMSQQP416, Type II Flange Diameter (inch) 03 Flange Height (inch) 002 Locking Insert Red Nylon (350?F Max Performance) Material Steel Maximum Installation Hole Diameter (inch) 0157 Minimum Installation Hole Diameter (inch) 0155 Outside Diameter (inch) 01 Overall Height (inch) 009 Performance Torque per

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Cadmium Plating New Method Plating Company Inc

Finish Cadmium plated per AMSQQP416, Type II, Class 1 and baked Heat treated components per AMSH6875 Weight 06 lb 10 Threaded Stud 11 Threaded Stud Thread Size 3/4 UNF 3A Finish Cadmium plated per AMSQQP416 Load Capacity 4,000 lbs in any direction Weight 10 09 lb, 11 10 lb Threaded Studs — These multipurpose, semiAMSQQP416 Plating, Cadmium (Electrodeposited) This document comes with our free Notification Service, good for the life of the documentSAE AMSQQP416, Revision F, March 21 (R) Plating, Cadmium Type II Treatment The prime purpose of Type II treatments on electrodeposited cadmium plating is to retard or prevent the formation of white corrosion products on surfaces exposed to stagnant water, high humidity atmosphere, salt water, marine atmosphere, or cyclic condensation and drying Type II

Ams Qq P 416 E Klzz15gdjqlg

Ams Qq P 416 E Klzz15gdjqlg

AMSQQP416 (Type II) (0003mm) Locking Cadmium Olive Drab to Dark Brown AMSQQP416 (Type II) (0003mm) FreeRunning & Locking Dry Film Lubricant Dark Gray to Black AS5272 (Type I) 2 Please Note May be completely or partially covered On average (of 6 readings) No single reading to be less than or greater than All nonAdapter Entry Size 4;Steel, cadmium plated (zinc plating option per ASTM B633 Type II, Fe/Zn 5) per SAEAMSQQP416, Type II, Class II Medium Pressure Hose Fitting Nuts (11) Fittings in accordance with MILDTL5070 Specifications for Fittings Material Aluminum and steel in accordance with Table I of MILDTL5070 Sizes 36 are steel Sizes 2 are all aluminum Finish Aluminum Alloy, anodized in

Page 367 Is Rayfast Catalogue Issue 9 17

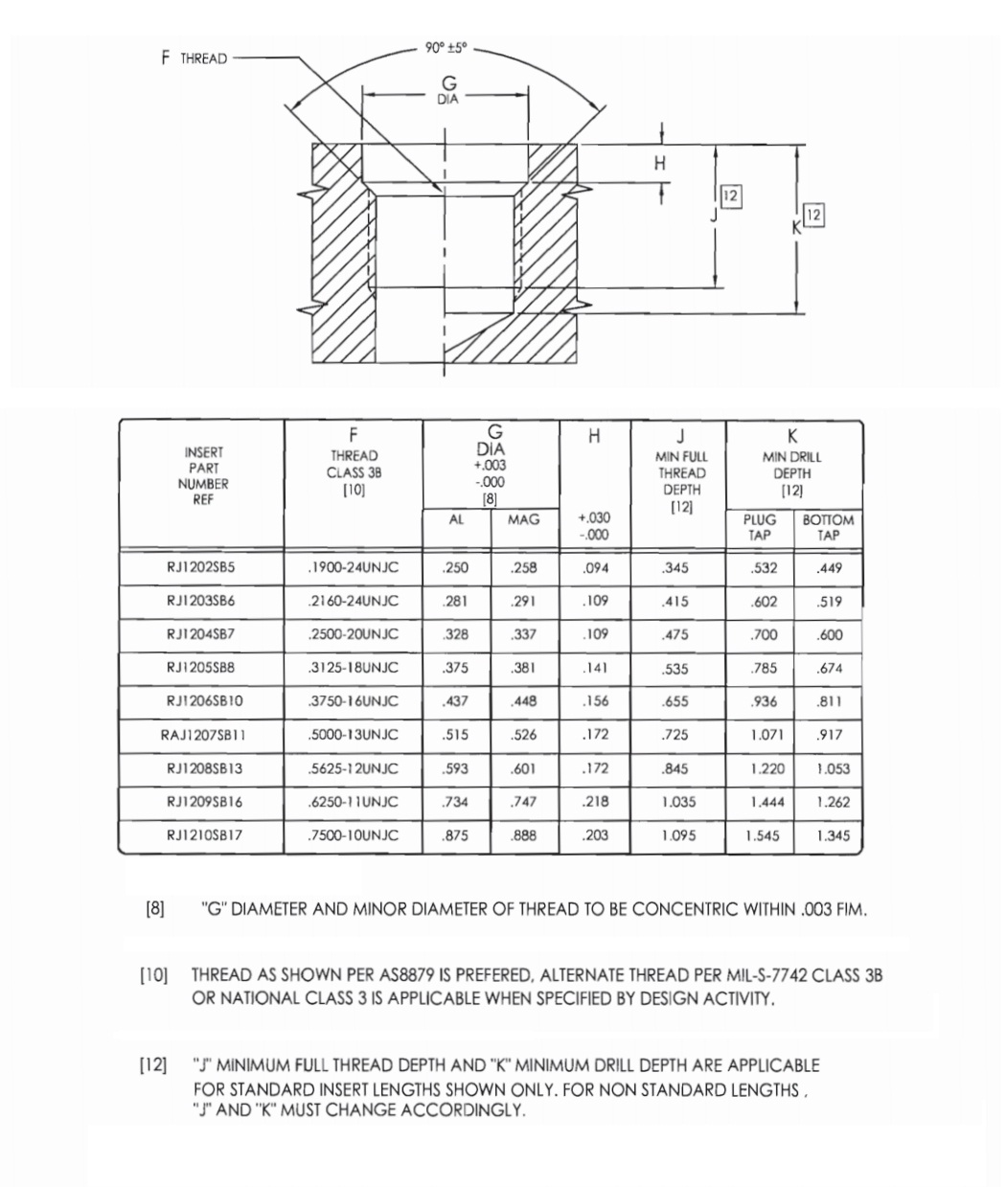

Rj10 Inserts Ring Locked Blind Fine Internal And External Coarse Threads On Howmet Aerospace

HST21PN( )( ) = Cadmium plate per AMSQQP416, Type II, Class 2 HEAT TREAT 160,,000 psi tensile per AMSH6875 MATERIAL Alloy steel per AMS6415, AMS6349, AMS6322, AMS6327 or AMS6325 alcohol lube per HiShear Spec 305 HST21CG( )( ) = Cadmium plate per AMSQQP416, Type II, Class 2, color green HST21PB( )( ) = Cadmium plate per AMSQQP416, Type II, Class 2Connector General Specification Number MILDTL · SAE AMSQQP416 March 1, 21 (R) Plating, Cadmium (Electrodeposited) General Usage Processes used for cleaning and cadmium deposition on components heattreated to, or having ultimate tensile strength of 152 ksi (1048 MPa) or higher tensile strength or 34 HRC or

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Sae Ams Qq P 416d 15 Sae Ams Qq P 416d 15 Plating Cadmium Electrodeposited

Technical Data Sheet Type 416 is a high chromium martensitic freemachining stainless steel Type 416 can be hardened by heat treatment to higher strength and hardness level Type 416 is used for any part that requires considerable machining, golf club heads, axles, gears and pinions, lead screws, valve trimAnd it is important with such coatings that the workmanship be such thatII – ″ minimum III – ″ minimum PLATING TYPES Type I – as plated Type II – w/ supplementary Chromate treatment INDUSTRY USES Aerospace, Automotive, Electronics, Defense, Marine and more

Cadmium Plating Mechanical Engineering General Discussion Eng Tips

Evaluation Of Alternatives To Electrodeposited Cadmium For Alcoa

Cadmium Plate, AMSQQP416, Class 2, Type I Cadmium Plate w/Chromate Dip, AMSQQP416, Class 2, Type II Cadmium plating is used on carbon steel to increase the corrosion resistance of the product The process of cadmium plating spiral retaining rings is costly and subjects the ring to the possibility of hydrogen embrittlement Smalley offers stainless steel as the preferable option toCaD Plate Per aMs QQP416 tyPe ii Cl2 CaD Plate Per aMs QQP416 , tyPe ii Cl2 CPr CaD Plate Per aMs QQP416 tyPe ii Cl2 GreeN Par 90 CaD Plate Per aMs QQP416 , tyPe ii Cl2 Par 90 Or Bare TABLE 1 strength requirements – CCr274 (Class 1), CCr264 (Class 2), CCr244 (Class 3) Rivet Material Head Class Minimum shear (lbs) Minimum Tensile (lbs) Minimum Torque out (inlbs)6122 Type II handling precautlon Chromate treatments (Type II), which involve only dipping in chemical soluttons, normally require a sufficent period of drying, approximately 24 hours at 70°F to 90°F (21°C to 32°C), to render the parts suitable for handlinq without damaqe to the coating while in gelatinous forms;

Dummy Receptacle Mil Dtl 264

Nasm Nut Datasheet Pdf Nut Equivalent Catalog

Ams QQP416 TYPE II 0187 0549 NAS1581F3R3 $059 F3R4 Ribbed Cruciform Alloy Steel (8740) 160,000 180,000 PSI Cadmium Per Ams QQP416 TYPE II 0250 0613 NAS1581F3R4 $040 C3T2 Cres (86) 160,000 190,000 PSI Passivate Per Ams 2700 0125 0487 NAS1581C3T2 $086 C3T3 Cres (86) 160,000 190,000 PSI Passivate Per Ams 2700 0187Cres passivate per astma967, type ii silver plate per ams2410 or ams2411or cadmium plate per saeams qqp416 type ii, class 2 solid film lubricant per as5272, type i, applied to threads only (a) minimum thread "h" in short lengths minimum thread "h" where length permits shall be 2 x diameter of thread (b) minimum length which may be specified example of part number nasAccordance with SAEAMSQQP416, Type II, Class 3 Plating code 2 electroless nickel in accordance with ASTM 33 Plating code 4 black anodize in accordance with MILA8625 Type II Class 2 Plating code 5 gold plated in accordance with ASTM B4 over electroless nickel in accordance with ASTM 3390 Plating code 6 chem film in accordance with MILC5541

Ams Qq P 416 E Corrosion Heat Treating

Flathead Threaded Insert Closed End Keyless Metric On Pennengineering

UNJF3B Nut Hex, High Tensile, Steel Steel Type C1137 OF FEDSTD66 or Carbon or Alloy Steel MILS1222 (C1137 Steel May Contain from 015 TO 035 perCENT LEAD), Cadmium Plate, SAEAMSQQ P416 Type II, Class 2 N1610 Series Show more Product certifications may be available for this product Please email customerservice@biscoindcom to inquire aboutAMSC, Class4, GradeB (Nickel) W W Cadmium, Olive drab over Electroless Nickel To meet AS requirements Y ZincCobalt, Dark Olive drab ASTMBB40 Z ZincCobalt, Black1075 Spring Steel or Equivalent CAD Plate per AMSQQP416, Type II, Class 2 (Yellow) 1075 Spring Steel or Equivalent CAD Plate per AMSQQP416, Type II, Class 2 (Yellow) *Add thickness to MHF or MHL chart dimension H2 –Subtract Thickness from MHF or MHL chart dimension P2 04,M3 06, 35 08,M4 10, M5 12, M6 0221 0265 0265 0312 0385 0375 0432 0045 0045

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

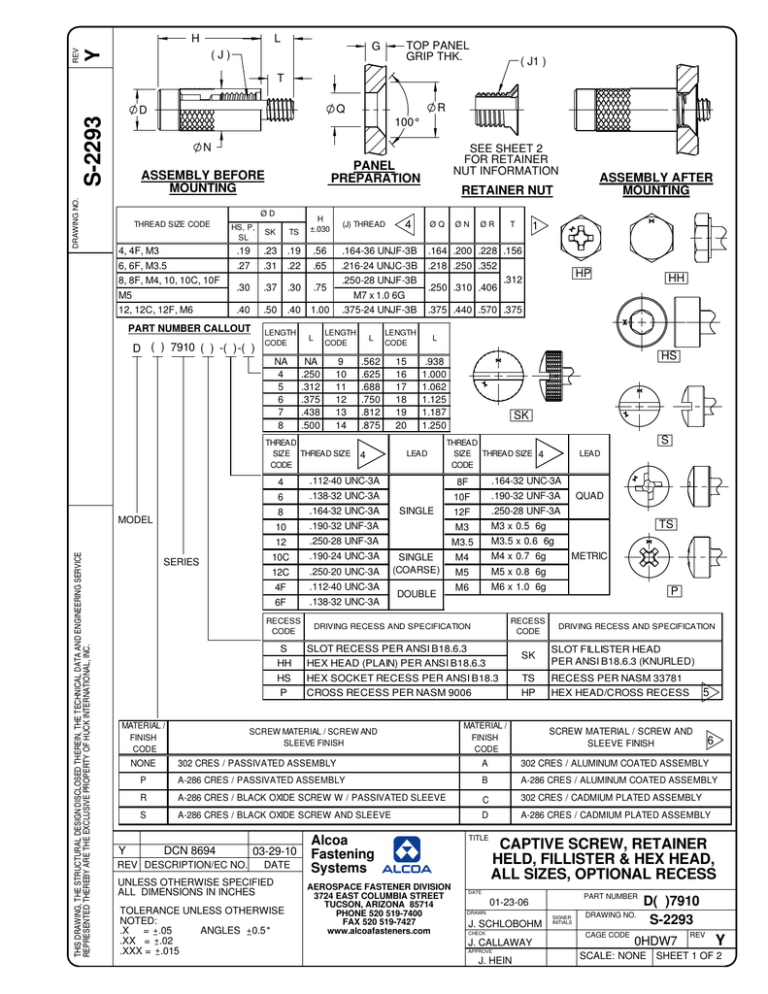

D 7910 Manualzz

Connector Detail Specification Number D399/; · Plating, Cadmium (Electrodeposited) AMSQQP416 This specification covers the requirements for electrodeposited cadmium platingAlloy 6061 per SAE AMSQQ00/8, Cadmium with Yellow Chromate Conversion per SAEAMSQQP416, Type II, Class 3 Over Nickel Underplate Aluminum Shell, Black Anodized Alloy 6061 per SAE AMSQQ00/8 or ASTMB221 Black Anodize per MILA8625, Type II, Class 2 Stainless Steel Shell, Passivated 300 Series, Passivated per SAE AMS2700

Ams Qq P 416 E Corrosion Heat Treating

Techmetals Earns Boeing Approvals Products Finishing

Steel, cadmium plated (zinc plating option per ASTM B633 Type II, Fe/Zn 5) per SAEAMSQQP416, Type II, Class II High Pressure Rubber Hose Fittings Fittings in accordance with MILDTL87 Specifications for Fittings Material Aluminum and steel in accordance with Table I of MILDTL87 All sizes are steel with aluminum sockets Finish Aluminum Alloy, anodized inAmsqqp416 (type iii) ams 2700 (method 1 type 1, 2) ossidazione anodica solforica del titanio (sulfuric acid anodizing of titanium) passivazione (passivation) cadmiatura elettrolitica tipo ii (cadmium plating type ii) trattamenti superficiali (surface treatments) ossid anodica cromica preparazione agli incollaggi (surface preparation for bonding) amsqqp416 (type ii) processiMultichrome/ Microplate processes Type I and Type II cadmium plating conforms to industry standards AMSQQP416;

Ccr274ss A Cres Solid Film Lube Passivate Ccr274cs P E R Per Per Per Ms604r Ams 5731 Astm A 493 Mil L Qq P 35 L F Pdf Free Download

Fy0lgyuzrqnyhm

· This specification covers the requirements for electrodeposited cadmium plating Cadmium plating shall be of the following types and classes, as specified (See 62) I As plated II With supplementary chromate treatment (See 3281) III With supplementary phosphate treatment (See 32) 1Type I, II and III anodizing touchup coatings used to process components of engines, actuators, landing gear and airframes, increasing their ability to perform and extending overall inservice life Cobalt Chromium Carbide to provide superior wear resistance and high temperature oxidation protection on engine components AeroNikl® – a sulfamate nickel which provides a defectfree,Overbraid Termination TinelLock Ring;

Passivation Of Stainless Steel Astm 67 Qq P 35 Ams 2700 Apt

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

Cable Entry Diameter2 – 64;FINISH Cadmium Plate, AMSQQP416, Type II, Class 2 PERFORMANCE Torque per NASM THREADS In accordance with AS79 before lubrication MARKING Only ø 3 and 4 SD on the area indicated on the drawing APPLICATION Type DA, DB and DC parts are particularly suited for use in applications involving installations in thin Aluminum or soft steel sheets or platesSPECIFICATION QQ – P – 416 / AMS – QQ –P – 416 Class 1 THICKNESS" min Class 2 THICKNESS" min Class 3 THICKNESS000" min Type I DETAIL As plated, no chromate Type II DETAIL With supplementary chromate treatment (SPI provides clear, gold and olive drab chromate) Type III DETAIL With supplementary phosphate treatment (This service is not offered

Countersunk Head Threaded Insert Closed End Keyless Unified On Pennengineering

Cadmium Plating Sheffield Platers

· QQP416F (NOTICE 1), FEDERAL SPECIFICATION PLATING, CADMIUM (ELECTRODEPOSITED) (28 MAR 02) S/S BY SAEAMSQQP416, QQP416F, dated 1 October 1991, with Amendment 3, dated 17 March 00, is hereby cancelled Future acquisition for this item should refer to SAEAMSQQP416, "Plating Cadmium (Electrodeposited)"Customer Service & Planning (along with others) have been instrumental in helping me work specific orders quickly and without their help we would be a lot farther behind than where we are so just wanted to send this quick thanks to recognize yourCable Diameter Range 32 – 51;

Page 16 Circular Connector Backshells And Accessories

Cadmium Plating Sheffield Platers

HST( )W = Cadmium plate per AMSQQP416, Type I, Class 2 See "Finish" note for explanation of other code letters HSTD8ADW = Assembly of HSTD8A collar and HST8DW washer Washer "C" 86 high temperature alloy per AMS5731 or AMS5737 HSTD8AWU = Assembly of HSTD8A collar and HST8WU washer THREAD PER 3 13 HST( )EW = HICadmium Type I, II Class 1, 2, 3 AMSQQP416 *QQP416 Electrodeposited Cleaning Surface Treatments MILS5002 TTC490 Chemical/Abrasive High Humidity Testing AMSSTD753 Method 101 Water Immersion AMSSTD753 Method 100 Copper Sulfate AMSSTD753 Method 102 Passivation AMS2700 *AMSQQP35 *QQP35 ASTM A 967 ASTM A 380 ChemicalSalt Spray Resistance 500;

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Cadmium Plating For The Aerospace Industry Har Conn

Cadmium Plating Sheffield Platers

Surface Finishes For Steel Fasteners Wilson Garner Company

An3 5a 100 Bolts Akcustom Hex Bolts

Precision Masking Difruscia Industries Inc

D7118

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

Item 40s79 6a 40s79 Steel Stud Assemblies W Slotted Head On Howmet Aerospace

Ams Qq P 416 E Corrosion Heat Treating

Hex40 Ab 90 17 A6 1 Ds Raychem Screened Backshells Adapters Te Connectivity

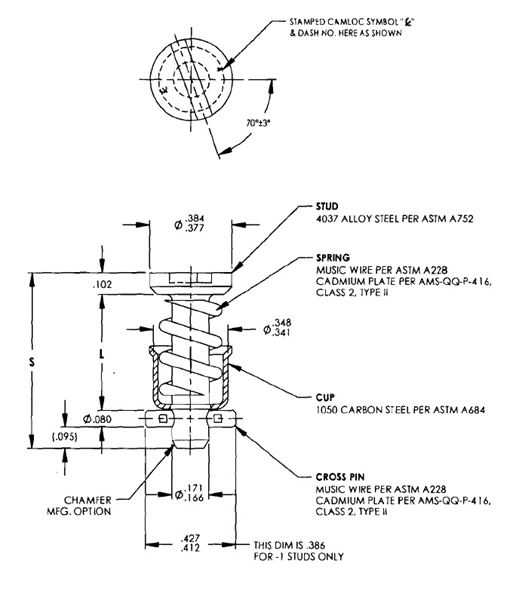

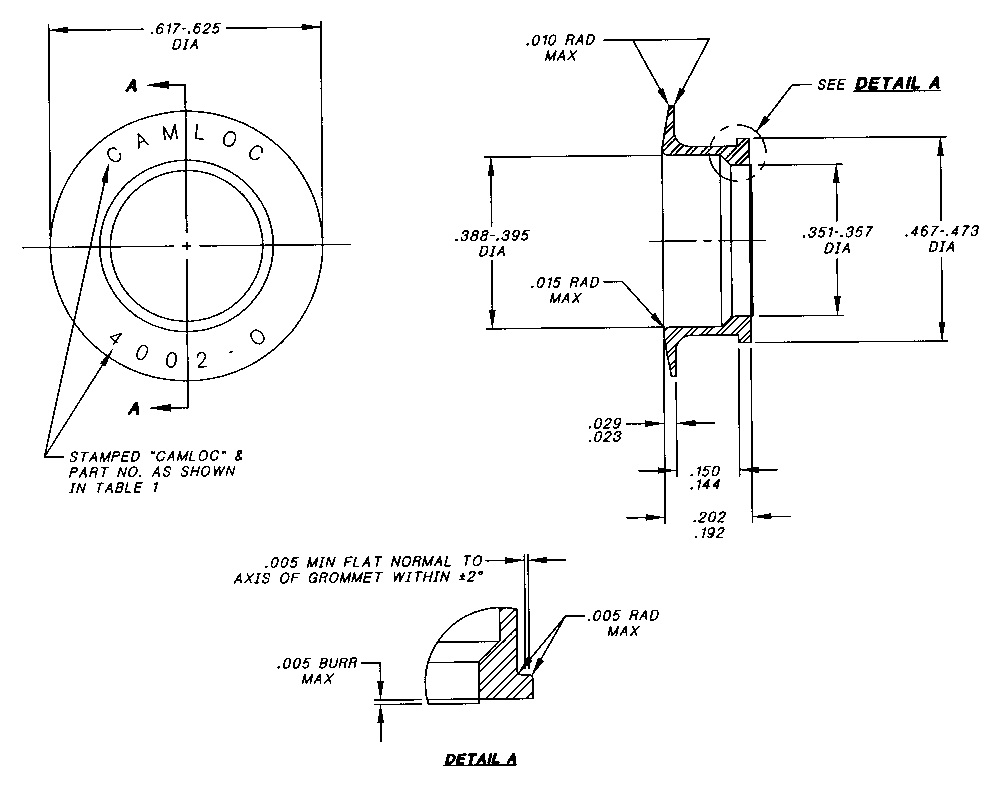

4002 O Grommets Plus Flush On Howmet Aerospace

Surface Finishes For Steel Fasteners Wilson Garner Company

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Thin Dense Chrome Plating Cadmium Plating Ams Qq C 3 Ams Qq P 416

Hex54 Ab 00 23 A10 1 Ds Raychem Screened Backshells Adapters Te Connectivity

Sae Ams Qq P 416 R Plating Cadmium Electrodeposited

Ams Qq P 416

Qq P 416 Tech Information

Cadmium Plating Atc 1 Stop Solution Provider For Quality Surface Finishing

Cadmium Plating Sheffield Platers

Cadmium Plating Coating Services Qq P 416

Coating

American Ring True Manufacturing Solutions

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

0 件のコメント:

コメントを投稿